Technology: Heat Pumps

Heat Pumps for District Heating

Heat pumps use electricity or fuel to drive a process, where heat at a lower temperature is “moved” to a higher temperature. In the process, a colder heat reservoir is cooled while a warmer heat reservoir is heated. The higher the temperature difference, the more input energy is needed per unit of heat delivered. The cold reservoir can be air, soil or water. The water can come from many sources, including ground water, rivers, sea. It can also come from geothermal sources or from waste heat. The ladder is relevant if these sources are not warm enough to be used directly in district heating. Air-source heat pumps are cheaper than ground source heat pumps, but have the limits that they usually do not work with air temperatures below -15’C and their efficiency is low with low outdoor temperatures.

Most heat pumps are working with compressors like a refrigerator. They are also called reverse refrigerators, where the cold parts are outside and the warm inside, opposite to a refrigerator. Heat pumps can also work with the absorption cooling principle.

Heat pumps for district heating typically have an efficiency, also called coefficient of performance (COP), around 3, meaning that 1 unit of electricity produces three units of heat by absorbing two units of heat from the ambient or from another cold heat source. The largest heat pumps (above 10 MW) often have a series of circuits, each provide a smaller temperature step. Heat pumps are mostly used in district heating systems with low temperatures: 60-70’C forward temperature and 30-40’C return temperature.

Examples

Hvide Sande District Heating

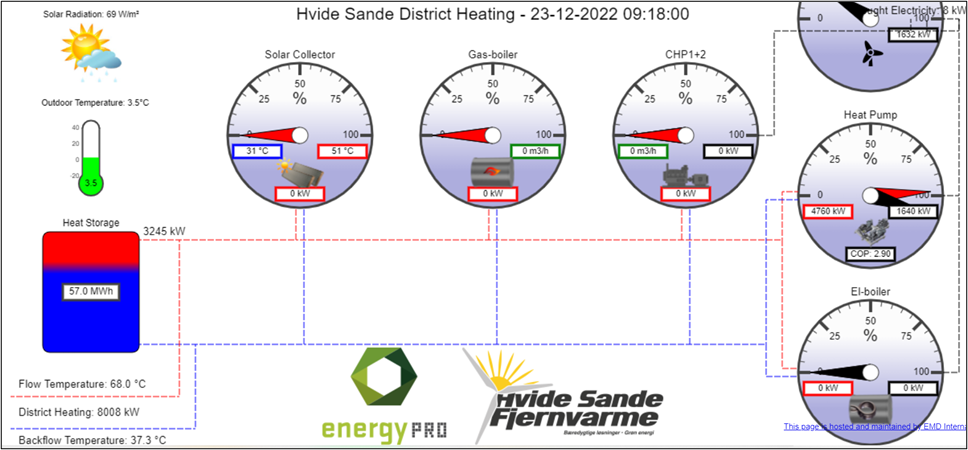

The town of Hvide Sande, Denmark with 2874 inhabitants have a district heating supply that combines gas CHP, solar heating, an electric boiler and a heat pump. The company also have two windmills that produce power which can either be used in the heat pump, in the electric boiler, or can be sold. Further, the company has a large heat storage tank. The company invested in a 4,88 MW heat pump in 2019, which is used whenever it is the least cost solution. Often the heat pump is used to produce heat with electricity from the wind turbines. Then there are no fees for power transmission and distribution. The combination of heat pump with CHP and windpower have been a very economic combination in the Danish market, where power sometimes can be sold for a high price. This has given record low heat price for the town.

Lem District Heating

In Lem, Denmark with 1296 inhabitants the district heating company invested in 2014 in a 400 kW absorption heat pump to supplement its existing the heating station with gas CHP, gas boilers and a wood chip boiler. The absorption heat pump is using heat from the wood chip boiler in its process. Then, in 2018, the company invested in 8140 m2 of solar collectors and in 2021 in a 4,2 MW air-water heat pump on a field near the town. To optimise the heat production with changing demand, changing energy prices and sunshine, the company now also have a heat storage with two water tanks that together holds 2,200 m3 of water.

Technical parameters

Sizes: varies from below 1 MW to close to 100 MW.

Efficiency (COP) depends on the hot and cold temperatures. The efficiency follows the ratio between the hot temperature (in Kelvin) and the difference between the hot and the cold temperature. As an example for heat pumps driven by electricity: if the hot temperature is 55’C (328 K) in average (of forward and return temperatures with, log average) and the cold temperature is 0’C in average, the theoretical COP is 333/55 = 6, but the practical COP is only half of that, COP=3) due to mechanical and thermal losses and irreversibilities. See precise formula in “sources for information” below.

For fuel driven heat pumps, the efficiency is the combination of the engine and the heat pump itself, typically around 150% from gas/oil input to heat output using ambient energy.

Lifetime: Technical lifetime 25 years.

Space requirements the heat pump itself is small and can be placed in a container (up to 3 MW):

- Air intake for air-air heat pumps is larger. Including space around is recommended 600 m2/MW heat. Also distance to neighbours must be considered because of noise from ventilators.

- Ground source heat pumps require brine tubes under around 30 m2 land per kW heat collected. For a 1 MW heat output heat pump with COP=3, the heat collected is 660 kW, which will require 19.800 m2 = 2 ha of land. The land can still be used for agriculture, recreation and others.

Emissions: There are no emissions during normal operation, but in case of accidents there can be emissions of refrigerants. Some refrigerants, HFCs, are string greenhouse gases while others are flammable (hydrocarbons as butane). Others are poisonous (as ammonia) or potentially suffocating in large quantities (CO2).

Financial parameters

Nominal investment:

- For air source HP including air intake, per MW heat output 860.000 – 1.400.000 € for sizes 10 – 1 MW.

- For HP without heat intake, per MW heat output 670.000 – 1.240.000 € for sizes 10-1 MW (the lower investment per MW for the larger units).

Fixed O&M: 2000 €/year per MW heat output.

Variable O&M: 1,7 – 2,7 €/MWh heat out for 10 – 1 MW with lower value for larger unit.

Sources for information

Calculation of energy and economy

Cases

- Hvide Sande Fjernvarme: hsfv.dk

- Lem Varmeværk: lemvarmevaerk.dk

- Live data for some district heating systems with heat pumps: emd-international.com